اشترك في نشرتنا الإخبارية وكن دائمًا أول من يسمع بما يحدث.

A Comprehensive Introduction to Calcium Carbonate

Aug 31, 2024Calcium carbonate (CaCO3 for short) is an inorganic compound, commonly in the form of white solid powder or granules, and is one of the most abundant substances on earth. It is widely distributed in nature and is the main component of rocks, corals, pearls and the shells of many organisms. Calcium carbonate is chemically insoluble in water, but can release carbon dioxide gas in an acidic environment.

Calcium carbonate can be divided into several types according to different production methods, particle size, morphology and uses. The focus of this discussion is to understand the difference between heavy calcium carbonate and light calcium carbonate, both of which are widely used in industrial applications.

Heavy calcium carbonate

Heavy calcium carbonate (GCC for short) is made by physical methods, usually mechanical crushing of natural minerals such as calcite, limestone, chalk, and shells. It is characterized by irregular particle shape, wide particle size distribution, and an average particle size of 5-10μm. Heavy calcium carbonate has a large bulk density, generally between 0.8-1.3g/cm³, and a low oil absorption value, generally 40-60mL/100g.

Light calcium carbonate

Light calcium carbonate (PCC for short) is produced by chemical precipitation. Its particles are regular in shape and can be regarded as monodisperse powders. The particle size distribution is narrow and the average particle size is generally 1-3μm. The bulk density of light calcium carbonate is small, generally between 0.5-0.7g/cm³, and the oil absorption value is high, generally 60-90mL/100g.

Active calcium carbonate

Active calcium carbonate is obtained by surface modification on the basis of ordinary calcium carbonate. It is hydrophobic and suitable for occasions with specific needs.

Difference

Production method: Heavy calcium carbonate is mainly produced by physical crushing, while light calcium carbonate is produced by chemical precipitation.

Particle size and shape: The particle size and shape of heavy calcium carbonate are irregular, while the particle size and shape of light calcium carbonate are regular.

Bulk density: The bulk density of heavy calcium carbonate is greater than that of light calcium carbonate.

Oil absorption value: The oil absorption value of heavy calcium carbonate is lower, while the oil absorption value of light calcium carbonate is higher.

Whiteness: The whiteness of light calcium carbonate is generally higher than that of heavy calcium carbonate.

Surface modification: Activated calcium carbonate has been surface modified and is hydrophobic.

Industrial application

Calcium carbonate is widely used in industry. It can be summarized into the following major areas:

1. Rubber industry

In the rubber industry, calcium carbonate is used as a filler and reinforcing agent in large quantities. It can effectively improve the hardness, wear resistance, tensile strength, tear resistance and aging resistance of rubber. In addition, calcium carbonate also helps to reduce production costs and increase the output of rubber products.

2. Plastic industry

In the plastic industry, calcium carbonate also plays an important role. It can improve the hardness, wear resistance, heat resistance and weather resistance of plastics, while also reducing production costs and improving production efficiency.

3. Construction industry

In the construction industry, calcium carbonate, as a raw material for cement, can significantly improve the compressive strength, flexural strength and durability of cement. It can also improve the construction performance of cement and improve the seismic performance of buildings.

4. Agricultural field

In the agricultural field, calcium carbonate is used as a fertilizer and feed additive, which can improve the disease resistance of crops, promote root growth and soil acid-base balance, and also improve the yield and quality of crops.

5. Medical field

In the medical field, calcium carbonate is used as a calcium supplement and antacid to treat diseases such as osteoporosis and rickets. It can also be used as a pharmaceutical excipient for the manufacture of tablets, capsules and injections.

6. Environmental protection field

In the environmental protection field, calcium carbonate is used as an adsorbent and precipitant to remove harmful substances from water, reduce the hardness of water bodies, and improve water quality. It can also be used in waste gas treatment and soil remediation.

7. Cosmetic industry

In the cosmetics industry, calcium carbonate is used as an additive for beauty products, which can improve skin texture, increase skin elasticity, and make the skin smoother and more delicate.

8. Other fields

In addition to the above application fields, calcium carbonate is also widely used in ceramics, glass, pigments and other industries. It can improve the hardness, wear resistance, corrosion resistance and transparency of materials and other performance indicators.

Processing

Processing of light calcium carbonate

Light calcium carbonate is produced by chemical reaction precipitation. Its production process mainly includes:

Calcination stage: calcine the limestone raw material to generate calcium oxide and carbon dioxide.

Digestion stage: put the calcined calcium oxide into a continuous digester and add water to digest it to obtain calcium hydroxide emulsion.

Carbonization stage: react the calcium hydroxide emulsion with carbon dioxide to generate calcium carbonate precipitation.

Dehydration and drying stage: dehydrate and dry the calcium carbonate precipitation to obtain dry calcium carbonate powder.

Crushing and screening stage: crush and grade the dried calcium carbonate through crushing and screening equipment to obtain the product of the required fineness.

Packaging stage: package the graded calcium carbonate powder to obtain the final product.

Processing of heavy calcium carbonate

The production process of heavy calcium carbonate generally includes the following steps:

Crushing: use a crusher to coarsely crush raw materials such as calcite for subsequent fine grinding.

Sorting: generally use hand selection, magnetic separation equipment or photoelectric separation equipment to remove impurities from the ore.

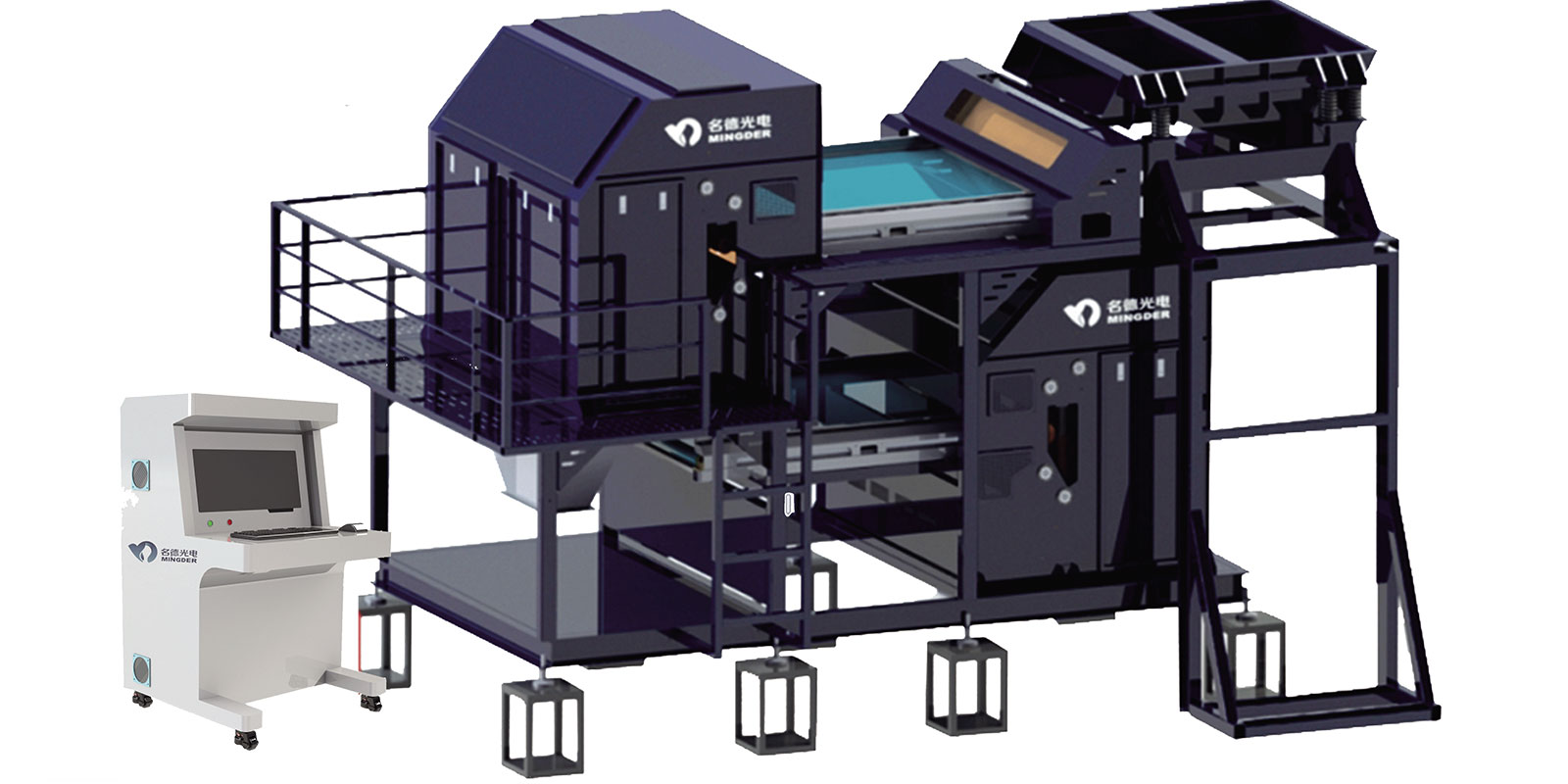

CCD Sensor Based Ore Color Separator

The color sorter and artificial intelligence sorting launched by Mingde Optoelectronics Technology Co., Ltd. have excellent performance in the sorting of heavy calcium carbonate. They can accurately compare the sorted materials according to the surface characteristics of the ore to achieve accurate sorting.

The heavy-duty sorting machine launched by the company can sort large-particle ore, which not only avoids over-crushing of the ore, but also increases the output of ore sorting.

Fine grinding: Fine grinding is carried out by Raymond mill, pendulum mill, roller mill and other equipment to obtain fine limestone powder.

Classification: The powder is graded by the classifier, and the powder that meets the particle size requirements is packaged and stored as a product, and the powder that does not meet the requirements is returned to the mill for re-grinding.

Packaging and storage: The powder that meets the particle size requirements is packaged and stored to complete the entire production process.

As a multifunctional and widely used material, calcium carbonate not only plays an important role in the traditional industrial field, but also shows new possibilities in emerging fields. With the development of science and technology, the application prospects of calcium carbonate will be broader.