اشترك في نشرتنا الإخبارية وكن دائمًا أول من يسمع بما يحدث.

New Method for Gold Ore Sorting - Photoelectric Sorting

Aug 30, 2024Gold has always been a dazzling word. It is a symbol of wealth and power, and it also carries the profound connotation of culture, history and religion.

At present, the main sources of gold are mining, recycling, sale and leasing by central banks and international organizations, and seabed mining.

Mining has always been the most traditional and stable source of gold, accounting for about 70% of the entire gold market.

Gold mines are widely distributed, and there are gold resources in many countries and regions around the world. According to the latest information, gold resources are mainly concentrated in Africa, Asia, South America, North America and Australia. Among them, Africa has the richest gold resources, and South Africa, Ghana, Senegal and other countries are the main gold production areas in Africa. Asia, especially China, Russia and India, also has a large amount of gold resources. Brazil, Peru and Colombia in South America are also important gold production areas. Canada and the United States in North America are the main gold production areas, and Australia is one of the most important gold resource countries in the world.

Gold mining is a complex and technology-intensive process, involving multiple links from exploration, mining, beneficiation to smelting. Gold mining requires not only advanced equipment and technology, but also environmental protection and safety production requirements.

Exploration is the first step in gold mining. The location and reserves of gold mines are determined through geological exploration technology. Preparatory work before mining includes infrastructure construction, such as building roads and setting up necessary facilities.

There are two main mining methods: open-pit mining and underground mining. Open-pit mining is suitable for surface deposits, while underground mining is suitable for deeper ore bodies. During the mining process, commonly used equipment includes drilling machines, blasting equipment and mine cars.

Ore dressing is to process the mined ore to extract the gold. Ore dressing processes include crushing, grinding, screening, gravity separation and flotation. Crushing and grinding are to reduce the particle size of the ore for subsequent processing; screening is to separate ores of different particle sizes; gravity separation and flotation are to separate gold and other minerals by physical and chemical methods.

With the continuous advancement of science and technology, photoelectric separation has also become an important way of gold ore separation.

It detects minerals through photoelectric sensors based on the optical properties of minerals, such as color, texture, gloss, shape, etc., to achieve mineral sorting.

Photoelectric sorting technology is developed on the basis of traditional mineral processing technology. It has the advantages of high efficiency, environmental protection, and energy saving. The sorting equipment mainly consists of four parts.

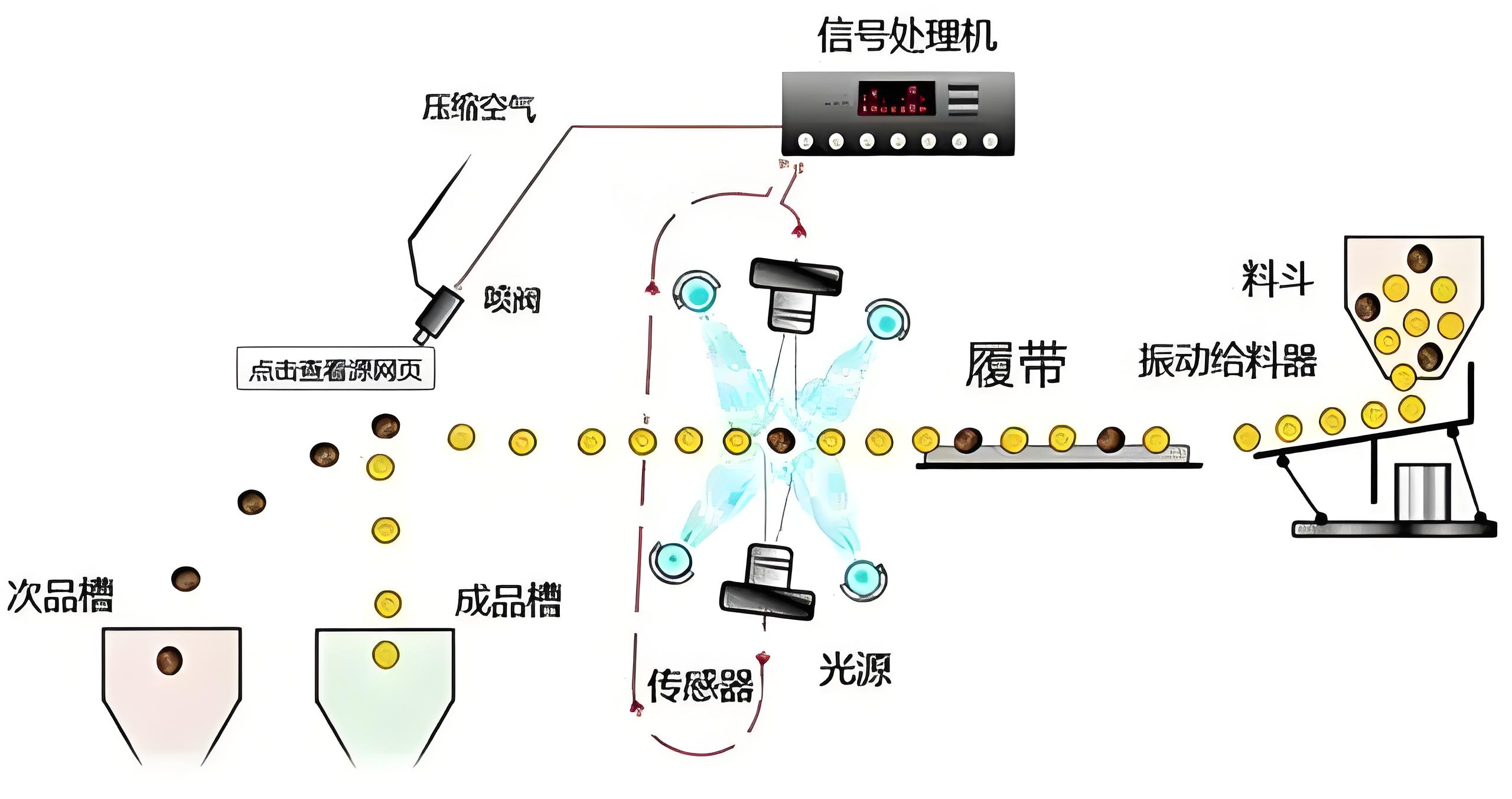

Feeding system: Through the vibrating feeder and crawler, the materials to be sorted are fed into the detection area of the photoelectric system at a constant speed to ensure the stability of the sorting effect.

Photoelectric system: It consists of a light source, a background plate, a sensor or an X-ray source, and a transmission plate. By collecting the comprehensive characteristics of the ore surface or the density difference, the ore is imaged in high definition, and the sensor is converted into an electrical signal to convey it to the electronic control system.

Control system: Receives the electrical signal transmitted by the photoelectric system, identifies and analyzes it, and through model training and learning, intelligently identifies and compares good and bad ores, and realizes the identification and sorting of non-massive ore data.

Sorting system: According to the instructions of the electronic control system, the defective products are blown into the defective product tank through the spray valve to achieve the sorting purpose.

The advantage of photoelectric sorting technology for gold mines is that it can improve the efficiency and accuracy of mineral processing while reducing environmental pollution. Compared with traditional physical and chemical mineral processing, photoelectric mineral processing has lower energy consumption, and the cost of mineral processing per ton is about 1 yuan, which is much lower than the average cost of traditional methods. In addition, photoelectric mineral processing has zero pollution to the environment and is a greener way of mineral processing.

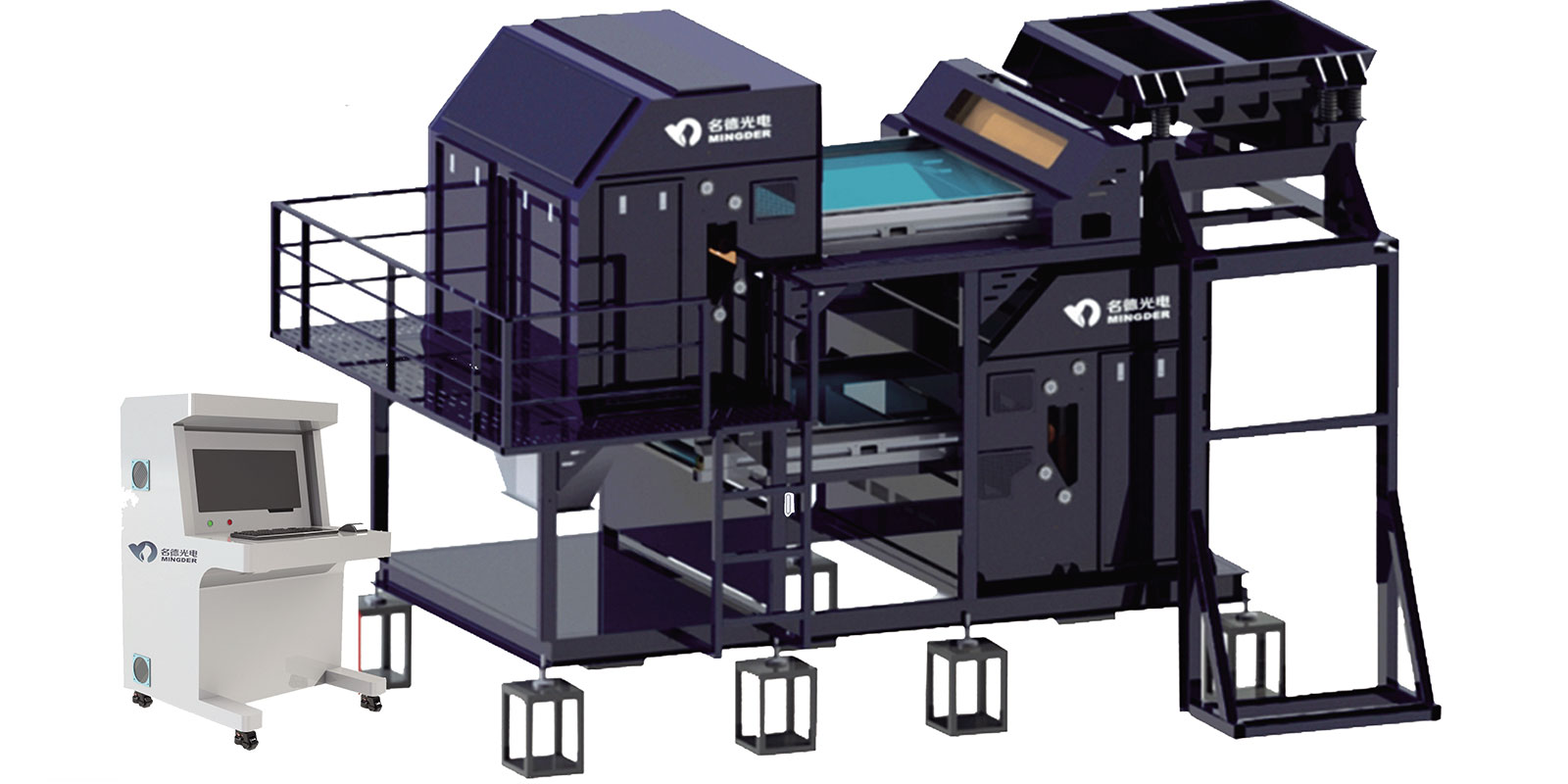

Hefei Mingde Optoelectronics Technology Co., Ltd. has been focusing on the research and development, production and sales of photoelectric sorting equipment since its establishment.

For gold mine sorting, the company currently has two main equipment solutions to choose from: for those gold mines with better dissociation and obvious surface characteristics of ore and impurities, the company's AI intelligent sorting machine can achieve effective sorting. For gold mines with good ores and impurity surface characteristics that are not obvious, the company has launched an X-ray intelligent sorting machine, which can combine the analysis of different densities of ore and impurities to achieve gold mine sorting.

X-ray Intelligent Ore Sorting Machine

Gold mines are an important natural resource, and their mining and processing have a profound impact on the national economy and the global market. With the advancement of science and technology and changes in market demand, gold mining and mineral processing technologies continue to develop and innovate to adapt to more efficient and environmentally friendly mining models. At the same time, as a metal with multiple functions, gold's position in the field of financial investment cannot be ignored. In the future, as the global economic landscape evolves, the gold mining industry and its related investment products will continue to play an important role on the international stage.