اشترك في نشرتنا الإخبارية وكن دائمًا أول من يسمع بما يحدث.

The Importance of Raw Ore Sorting

Aug 17, 2024Ore sorting is an important link in the mineral processing process, which is directly related to the efficiency and cost of the subsequent mineral processing process. The significance of raw ore sorting is mainly reflected in the following aspects:

Improve ore grade: Through sorting, low-grade ore or waste rock can be removed, and the average grade of ore entering the subsequent mineral processing process can be improved, thereby reducing ineffective operations and reducing mineral processing costs.

Optimize mineral processing technology: According to the physical properties of the ore, such as specific gravity, magnetism, optical properties, etc., the ore is preliminarily sorted, which can provide better raw materials for the subsequent mineral processing process and improve the mineral processing efficiency.

Reduce mineral processing costs: Raw ore sorting can reduce the processing volume of low-grade ore, save energy and reagent consumption, and thus reduce the unit cost of mineral processing.

Reduce environmental pollution: The pre-thrown tailings can be used as building materials or mine backfill without grinding, reducing the discharge of solid mineral waste and reducing the burden on the environment.

Improve economic benefits: Through raw ore sorting, not only can the mineral processing efficiency be improved, but also the economic benefits of the enterprise can be increased, bringing more profit space for the enterprise.

Technological development of raw ore sorting

Ore sorting technology has gone through a development process from simple manual selection to mechanization, automation and even intelligence. In recent years, with the advancement of artificial intelligence and photoelectric sorting technology, raw ore sorting technology has been significantly improved. Intelligent sorting technology can efficiently sort according to the different surface characteristics of ore, such as texture, color, texture, shape, etc., which greatly improves the accuracy and efficiency of sorting.

The key role of raw ore sorting in the mineral processing process

The key role of raw ore sorting in the mineral processing process is mainly reflected in the following aspects:

Reducing grinding load: Through raw ore sorting, a part of the waste rock that does not need to be ground can be removed, reducing the load of the mill and improving the grinding efficiency.

Improving mineral processing indicators: Raw ore sorting can improve the overall grade of the ore, provide higher grade raw materials for subsequent mineral processing operations, thereby improving mineral processing indicators.

Reducing tailings content: Through raw ore sorting, a part of the tailings can be pre-thrown before grinding, reducing the generation of tailings, reducing the pressure of the tailings pond, and reducing environmental pollution.

Improve resource utilization: Ore sorting can improve the utilization rate of low-grade ores, reduce the waste of mineral resources, and achieve efficient utilization of resources.

The impact of ore sorting on improving ore dressing efficiency

The impact of ore sorting on improving ore dressing efficiency is mainly reflected in the following aspects:

Improve ore dissociation degree: Ore sorting can improve the ore dissociation degree and provide more favorable conditions for subsequent ore dressing operations.

Reduce over-grinding: Through ore sorting, it is possible to avoid grinding the ore that has been dissociated again, reduce over-grinding, and reduce grinding costs.

Improve ore dressing recovery rate: Ore sorting can improve the recovery rate of useful minerals, especially for complex and difficult-to-select ores, ore sorting is the key step to improve ore dressing recovery rate.

Reduce ore dressing costs: Ore sorting can reduce the energy and reagent consumption in the grinding and sorting process, thereby reducing the overall ore dressing cost.

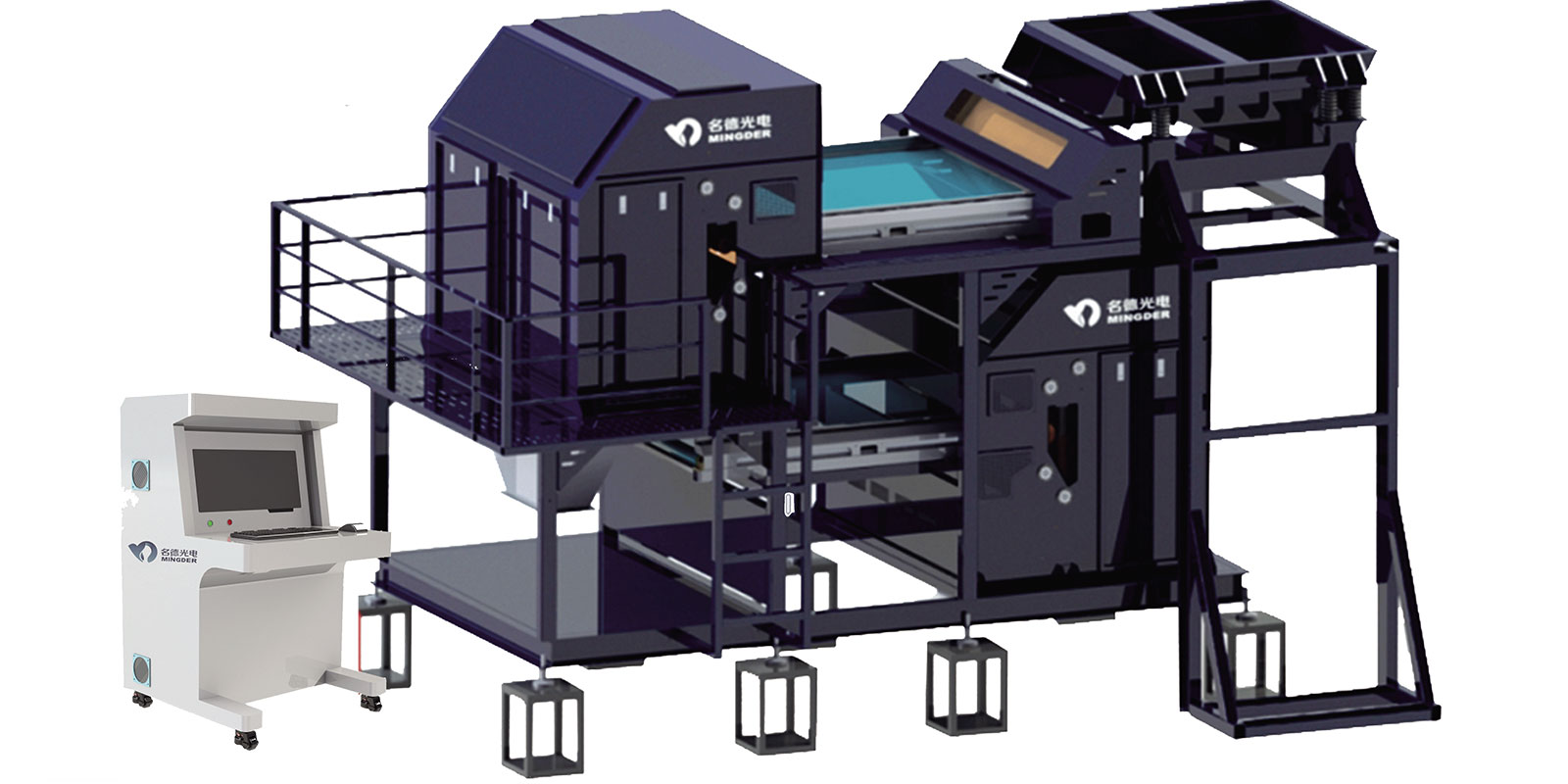

Since its establishment, Mingde Optoelectronics Technology Co., Ltd. has been specializing in the production of raw ore intelligent sorting equipment and has accumulated extensive experience in optoelectronic sorting technology. The company's main products include ore color sorter, AI intelligent sorting machines, X-ray intelligent sorting machines, foreign body removal robots and mining automation production lines. The company has built a production and R&D base of more than 40 acres, with 20,000 square meters of standardized factory buildings and scientific research centers, and has a complete R&D, design, manufacturing, sales and service system.

At present, the company has obtained more than 80 core patent technologies with independent intellectual property rights in the fields of artificial intelligence, big data, and mineral processing.

CCD Sensor Based Ore Color Sorting Machine

For more than 10 years, the ore sorting equipment of Mingde Optoelectronics brand has been widely used in various metal, non-metallic mines and enterprise sites with its excellent performance and perfect service.

In summary, raw ore sorting plays a vital role in the mineral processing process. It can not only improve mineral processing efficiency, but also reduce costs, improve resource utilization, and reduce environmental pollution, which is of great significance to the improvement of corporate economic benefits. With the continuous advancement of science and technology, raw ore sorting technology will continue to develop and improve, bringing greater changes to the mining industry.